Have Couplers, Will Travel

This article first appeared in the August/September 2021 issue of Adventure Cyclist magazine.

Dwan Shepard of Co-Motion Cycles calls the S&S coupler the finest bicycle component ever made.

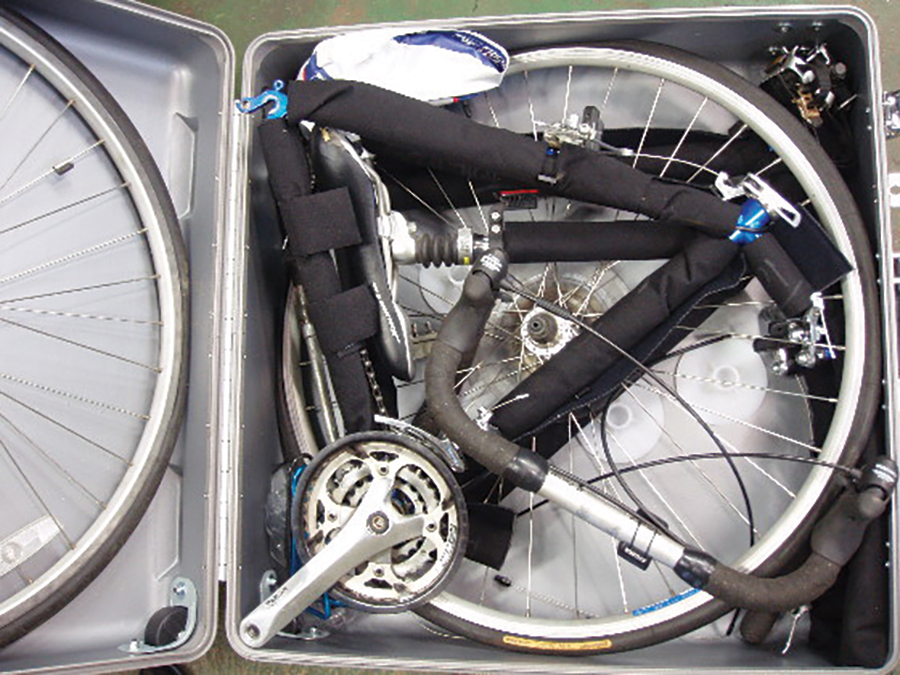

For the uninitiated, the S&S coupler is a precision lug installed in the top and down tubes of a bicycle frame that allows it to be broken in half and packed into a suitcase that can be checked as regular luggage.

In every other way, an S&S-coupled bike is completely traditional, which is one of the appeals of the clever device. You don’t have a folding bike. You have your regular bike, only you can fit it in a suitcase. A lot of cyclists find that to be the best of both worlds.

“You cannot find a flaw in that thing, and there is no other component we’ve ever used that is as flawless and reliable and trusted as that part,” Shepard said of the coupler.

In fact, Shepard said, if the coupler doesn’t fit perfectly into a bicycle tube, it means the tube is off, not the coupler.

“Tubing manufacturers have had to clean up their act because you know the coupler is the right size,” he said. “If it doesn’t go in, you know it’s the tube.”

Shepard said the S&S coupler is an “extraordinarily popular option” for Co-Motion buyers. Close to half of the company’s orders for tandems include S&S couplers. The same goes for singles.

“You’re already thinking about a bike that is maybe your dream bike to ride across the country or across some continent or around the world,” he said. “The idea that you can have that bike pack into a travel case so you can check it onto a plane and fly anywhere with it, it’s pretty hard to resist that.”

Co-Motion was the first bike builder to offer the coupler as a standard option, after Shepard saw it in action at Interbike in 1994. The inventor, Steve Smilanick of S and S Machine in Roseville, California, had a display set up at the show that explained how the coupler was tested to prove they were stronger in bending, torsion, and tensile strength than the tubing itself.

‘You cannot find a flaw in that thing, and there is no other component we’ve ever used that is as flawless and reliable and trusted as that part.’

“He started out with the proof, laid it out there to see,” Shepard said. “The remarkable thing is you can’t argue with it. Here we are 25 or more years later, and we’ve never seen one of these couplers fail. I’m inclined to believe him.”

Smilanick made the first coupler for himself. He had been recruited by his mother to take his daughter and his niece on a Mediterranean cruise, filling the role she normally played with her grandchildren.

“I tried everything to get out of it, but she wouldn’t take no for an answer,” Smilanick said.

Smilanick decided if he had to take a cruise, he wanted to bring his bike with him. When his travel agent told him he couldn’t because a bike was too big, he asked if he could take it if it was smaller. When the answer came back yes, Smilanick, a machinist by trade, set about figuring out how to fit his bike into a duffle bag, and came up with the first coupler — a crude version compared to today’s design.

“It didn’t have the taper on the teeth, didn’t have the nice profiles, it wasn’t optimized for weight, it wasn’t made from heat-treated 17/4 stainless steel,” Smilanick said. “It was not intended to use over and over.”

Smilanick took his bike on that cruise and did 50- to 90-mile rides every day the ship was in port.

“Honestly, I’m not a traveler,” he said. “You’d think a guy who devised something for travel would be a traveler.”

The S&S coupler looks deceptively simple. You line the teeth of the couplers up and slide the frame together, securing the device with a threaded collar, using a special wrench.

Smilanick explained that the tapered teeth don’t bottom out in order to achieve a joint that doesn’t allow micro-movements. He said the angle of the taper is important.

“If it’s too flat, the teeth can move,” Smilanick said. “If it’s too tapered, the teeth can lock together.”

Smilanick declined to say what that exact angle is, determined through a process of trial and error. The 17/4 stainless steel was selected for its resistance to corrosion and very high strength so it can be heat-treated after machining.

Hundreds of bike builders use Smilanick’s coupler. He says he gets at least one inquiry every week, but Smilanick said the coupler is “not how we make our living.”

“I do it because of the kind of feedback I get from people,” he said. “When I used to go to Interbike, people would come up to me and thank me.”

A lifelong cyclist, Smilanick, 71, said he was one of the few kids in his neighborhood who wanted to ride his bike to kindergarten. He took a break from cycling in his 20s and early 30s, but then returned to it and has ridden ever since — until recently.

“I rode up until about five years ago,” Smilanick said. “I only quit because I had a cousin who, while on a motorcycle on the Santa Monica freeway, was killed by a road rage–type driver. I began to feel it’s not a matter of if, but when.”

From 33 to 65, Smilanick said he rode 10,000 miles a year.

“I love bicycles,” he said. “I do miss it. I see people on bikes and think, ‘That looks like fun.’”

Smilanick was destined to become a machinist. Growing up, he idolized his uncle, who was a tool and die maker.

“He was a magician as far as I was concerned,” Smilanick said. “If you needed something, he would build it. It always intrigued me that if something on my minibike was broken, we went to see Uncle Johnny. He could fix or build anything.”

Smilanick got a degree in industrial technology, plus a teaching degree, and started teaching metal shop at the high school and junior college level. He founded S and S Machine in 1973, making a variety of parts for the auto industry and others. In 1976, one of his students suggested they begin making commercial salmon fishing gurdies, which are used to reel in the stainless-steel fishing lines.

Smilanick incorporated S and S Commercial Fishing Equipment Inc., marketing his gurdies for $400.

“I sold tons of them,” Smilanick said.

But that ended in 1980, when the Pacific Coast Fishing Commission reduced the size of the fleet to protect salmon from overfishing. Smilanick’s gurdie market disappeared overnight. By the next year, he was making parts for a manufacturer of computer floppy disk drives and never looked back. Today, he machines everything from parts for medical instruments to test fixtures for motherboards.

‘You’d think a guy who devised something for travel would be a traveler.’

S and S today occupies about 30,000 square feet and has about 28 employees, manufacturing custom precision parts using computer-controlled machine tools. The bike coupler is S and S’s only product in the traditional sense of the word, as everything else the company does is as a job shop.

“This coupling is the only thing I build for myself, which is why it’s a misfit for me,” Smilanick said. “I have toyed with the idea of selling that portion of my business. It still may be imminent. Pre-COVID, I was in discussions with a bike builder. There are about three companies I could see selling my business to.”

Neither Smilanick nor Shepard would say whether one of those companies is Co-Motion, but it wouldn’t be surprising. Shepard declined to say how many S&S couplers he uses in a typical year, but Co-Motion is certainly one of the leading customers for the device.

My wife and I bought Co-Motion Siskiyous with S&S couplers in 2018 after our fifth European tour using rented bikes. We finally grew tired of taking our chances on bikes that ranged from acceptable to downright awful. When we decided to take the leap, I thought of one company and one configuration, and we haven’t been disappointed.

We took our bikes to the U.K. for a tour of the Cotswolds in 2018 and to Sicily for a ride across that remarkable island in 2019. We were planning a tour of Denmark for 2020 when the COVID-19 pandemic hit and turned the world upside down. Hopefully, we’ll take that Danish tour in 2022.

I’ll be honest, it’s not easy to pack a full-sized bike into a suitcase that can be checked as normal luggage, even with the magical couplers. But when you’re riding down a lane in the Cotswolds on the same comfortable, responsive, hand-made bike that you use back home on the backroads of Vermont, there’s something really special about that.

“Until the S&S coupler came along, everybody laughed at the idea of taking a regular bike frame and splitting it in half for travel,” Dwan Shepard said. “Steve proved that he could make a removable joint essentially that was tougher than the tubing itself, and it only added a few ounces per coupler. And because of the precision of the machining and the quality of the material, it could be used over and over again.”